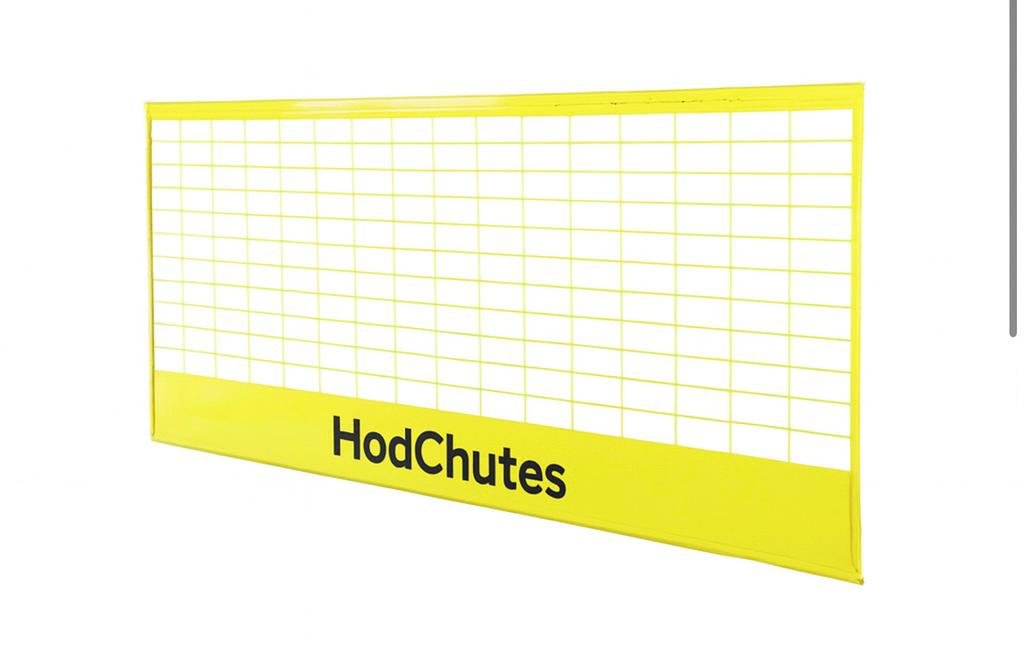

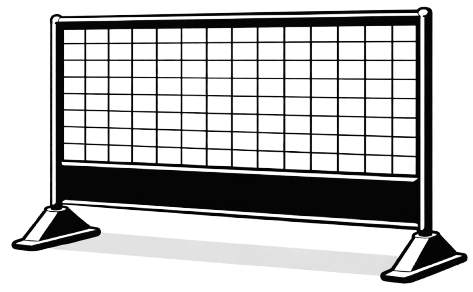

Steel Edge Protection System for Construction Sites

Engineered steel guardrail panels for fall protection and dropped-object prevention on active job sites

- OSHA-aligned guardrail system

- Reduces fall and dropped-object hazards

- Reusable steel panels for multiple projects

- Faster installation than site-built wood

Who It’s For

Built for construction professionals responsible for job-site edge safety.

General Contractors

Managing edge protection across commercial and multi-family projects.

Safety Managers

Overseeing fall-protection systems and site-wide guardrail consistency.

Subcontractors

Installing edge protection on balconies, decks, shafts, and elevated work areas.

System Components

Modular steel components designed for fast installation and reliable performance on US construction sites. All dimensions are shown in Imperial units first, with metric in parentheses.

Length

Metric Length

Height

- 39.4 in

- 1.0 m

- 42 in

- 49.2 in

- 1.25 m

- 42 in

- 59.0 in

- 1.5 m

- 42 in

- 78.7 in

- 2.0 m

- 42 in

- 98.4 in

- 2.5 m

- 42 in

Dimensions & Sizes

Standard Height

All guardrail panels feature a fixed height of 42 inches (1 m) to meet strict OSHA and EN 13374 safety requirements. Ideal for flat surfaces, balconies, and stairs.

- One compliant height- no guesswork on site.

Designed for OSHA Standards

Designed to align with OSHA guardrail requirements through rigid steel construction, consistent panel connections, and secure attachment at exposed edges. Engineered and tested to EN 13374 for added structural reliability on demanding construction sites.

Project Scope & Applications

This steel edge protection system is used on a wide range of construction projects where consistent fall protection is required.

- Commercial high-rise construction

- Multi-family residential buildings (apartments & condominiums)

- Industrial and warehouse facilities

- Infrastructure and critical construction projects

- Renovation, retrofit, and upgrade work

Designed for use on slabs, balconies, decks, and exposed edges throughout all project phases.

Consistent Installation

Pre-engineered components deliver uniform guardrail placement across every job site.

Faster Setup

Modular panels reduce installation time compared to field-built wooden guardrails.

Professional Appearance

Clean, uniform edge protection that reflects well during inspections and client walkthroughs.

Built for Reuse

Designed for repeated deployment across multiple projects without rework or waste.

Why Steel Edge Protection Outperforms Wood

- Eliminate On-Site Labor : Stop cutting, fastening, and rebuilding wooden guardrails. Pre-engineered steel panels install quickly without field fabrication.

- Permanent Safety Asset : Unlike disposable lumber, steel edge protection is reusable across multiple projects, reducing waste and long-term cost.

- Consistent Structural Performance : Steel maintains strength and alignment over time, unlike wood that can warp, crack, or loosen on site.

Why Steel Edge Protection Is the Professional Choice

Designed to align with OSHA guardrail requirements through rigid steel construction, consistent panel connections, and secure attachment at exposed edges. Engineered and tested to EN 13374 for added structural reliability on demanding construction sites.

OSHA-ready protection for every job site.

Why wooden guardrails are risky?

When edge protection fails, workers face serious fall hazards and the risk of tools or materials falling to levels below.

- Higher risk of fall-from-height incidents

- Dropped tools or materials can injure workers below

- Inconsistent protection across crews and job sites

The Smart Contractor’s Alternative to Wood

Wood Guardrails

Steel Edge Protection

- Single-use

- Can fail

- Unprofessional look

- Higher OSHA risk

- Labor intensive

- Reusable

- Consistent strength.

- Professional appearance

- Compliance-focused

- Faster installation

Invest in Safety That Pays for Itself

Steel edge protection is not a consumable job-site expense , it’s a capital safety asset.

Instead of rebuilding wooden guardrails on every project, contractors invest once in a reusable system that supports multiple sites, crews, and timelines.

How the system delivers long-term value:

- Eliminates recurring lumber and disposal costs

- Reduces repeated labor spend across projects

- Retains value as a reusable safety asset

- Improves cost predictability for future bids

Steel Edge Protection in Active Construction Environments

Installed on active job sites to control fall hazards and dropped-object risks in real working conditions.

Perimeter edge protection on elevated slab

Dropped-object containment at exposed edges

Fall protection was installed during active steel erection

Request Pricing for OSHA-Compliant Steel Edge Protection

Frequently Asked Questions

How does steel edge protection reduce labor compared to wood guardrails?

Steel systems install without cutting or rebuilding, saving labor hours on every project.

Does this system meet OSHA guardrail requirements?

Yes. The system is designed to align with OSHA 1926 guardrail standards when installed correctly.

Can this system help prevent dropped-object hazards?

Yes. The system provides consistent edge containment to reduce the risk of tools or materials falling to lower levels.

Is the system reusable across multiple job sites?

Yes. Steel edge protection is designed for repeated use across projects without performance loss.

Is this system available for purchase or rental?

Both purchase and rental options are available depending on project needs.